These days, articles about artificial intelligence are usually prefaced with a wordy introduction (often written by AI itself!) about how AI is revolutionizing industry A-Z and with a brief historical context of the developments. But you already know this, right?

So instead let’s start with a prediction…

In the future every engineering action will be assisted.

What this means concretely is that the following systems and requirements processes won’t be done by a single person anymore, but by a person or team collaborating with an AI.

Already, right now, today, AI is making the lives of systems and requirements engineers easier (see valispace.com/ai).

In this article we talk about why engineering companies should seriously consider AI assistants in their day to day workflows, and suggest that not preparing to embrace AI for systems engineering practices will be an existential threat.

Early stage requirements gathering: Going from 0 to 1

Lots of engineering work consists in coming up with solutions to novel problems. However, staring at a blank page is as much a problem for creative engineering work as it is for writers of novels. It is much easier to start from a draft that you edit to your needs than to try thinking of everything yourself.

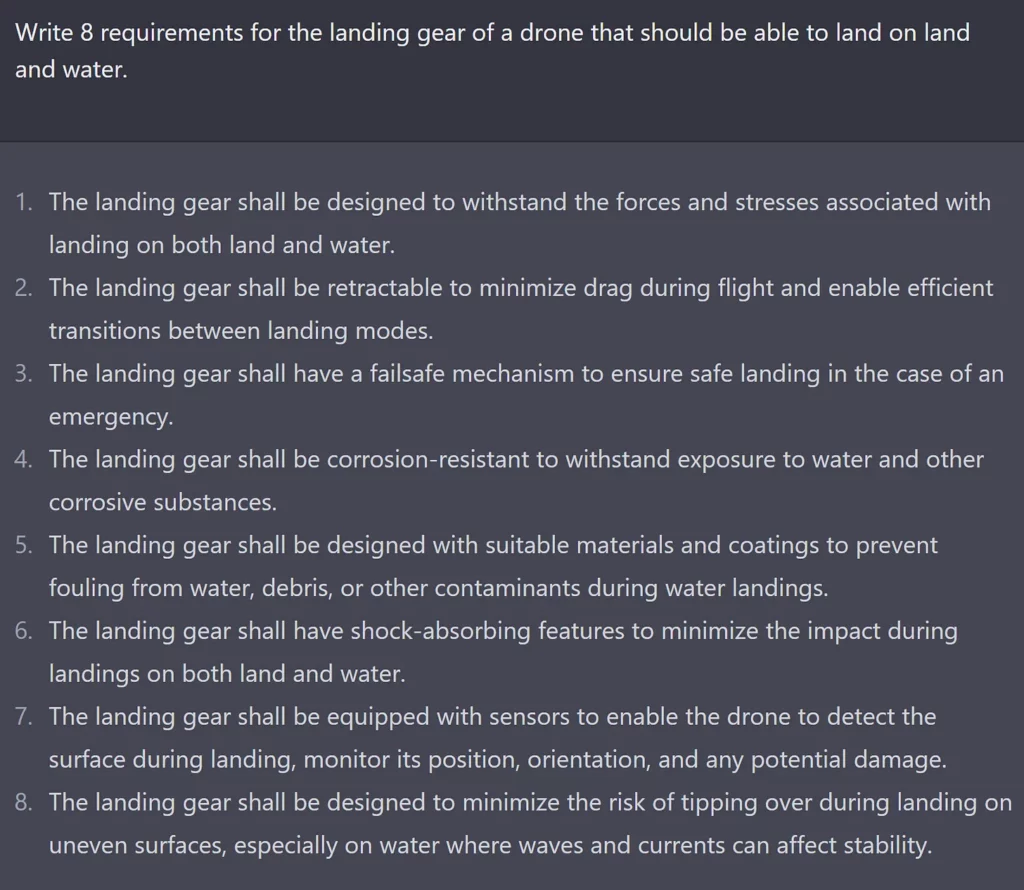

AI Assisted Engineering allows you to brainstorm within seconds a starting point to many potential aspects. Consider that you are e.g. tasked to design the landing gear of a drone. Instead of trying to think of all the aspects that might be relevant to this piece of equipment you can start discovering which aspects your solution needs to cover:

And suddenly we are ready to think about lots of aspects. Not only about the landing gear itself, but also to think about drag forces, failure cases, material-choices, shock, monitoring and risk management.

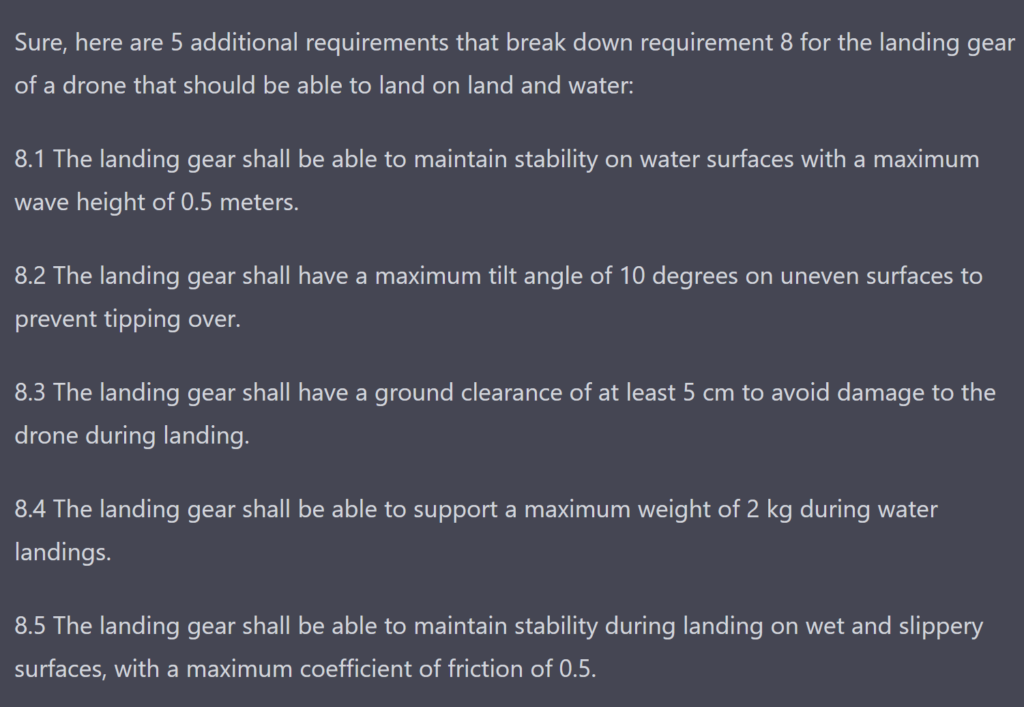

These requirements are far from being good or final, but within seconds we are in the middle of thinking about the detailed design. The Results have accelerated us and we can now start diving deeper into multiple aspects:

And here we are. Within minutes we have reached the point in which we are able to consider and formulate requirements that are testable.

Do these requirements need work and refinement, before sending them out to a supplier? Absolutely. Do the values need to be thought through and checked with other stakeholders? Definitively. Did we arrive here 10x as fast as we would have without AI Assisted Engineering? You bet.

Data driven insights and retrieving existing information

Engineering work also contains a non-trivial amount of trying to find the correct information that is needed at a given point for decision making. These may be values from datasheets, requirements, verification methods, etc.

Structured engineering data, such as in PLM and EIM tools is already helpful, since data exists in these tools in machine readable format instead of PDFs and other documents. However, AI Assisted Engineering capabilities will allow engineers to ask questions to retrieve data easily, both when interacting alone in front of a PC or when enhancing a conversation in a meeting room.

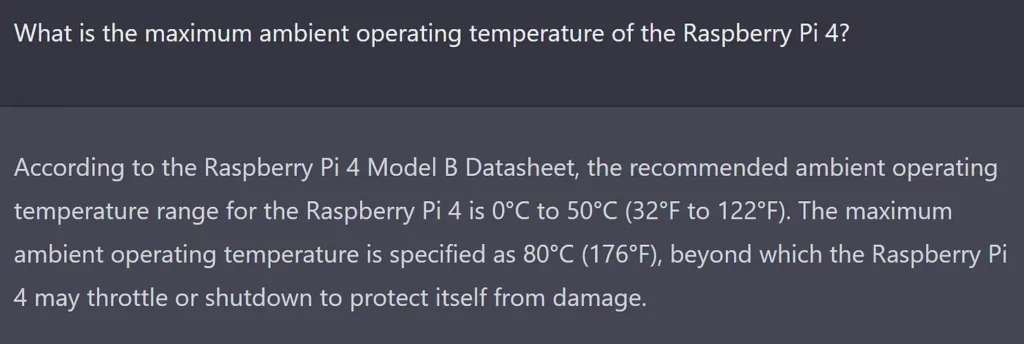

Imagine that an engineering team is considering using a Raspberry Pi for an early prototype for a sensor in a foundry that they are developing. When someone brings up the fact that the ambient temperature might be too high for the electronics to survive, the pace of the meeting can continue high, if instead of it being interrupted by people looking through documentation you can just ask during the meeting:

Triggering Simulations from text

But of course not all of engineering is based on text alone: engineering requires parameters, formulas, physical units and their interactions to derive meaningful designs. But even in this case, AI assisted engineering capabilities will allow the interactions to be sped up significantly.

Once you combine natural text input with access to data-driven engineering and simulation tools you can on the fly generate accurate answers for hypothetical scenarios. Valispace’s video (from 2018!) visualizes best what such an interaction can look like and why the difference in getting an answer changes how fast your engineering can advance.

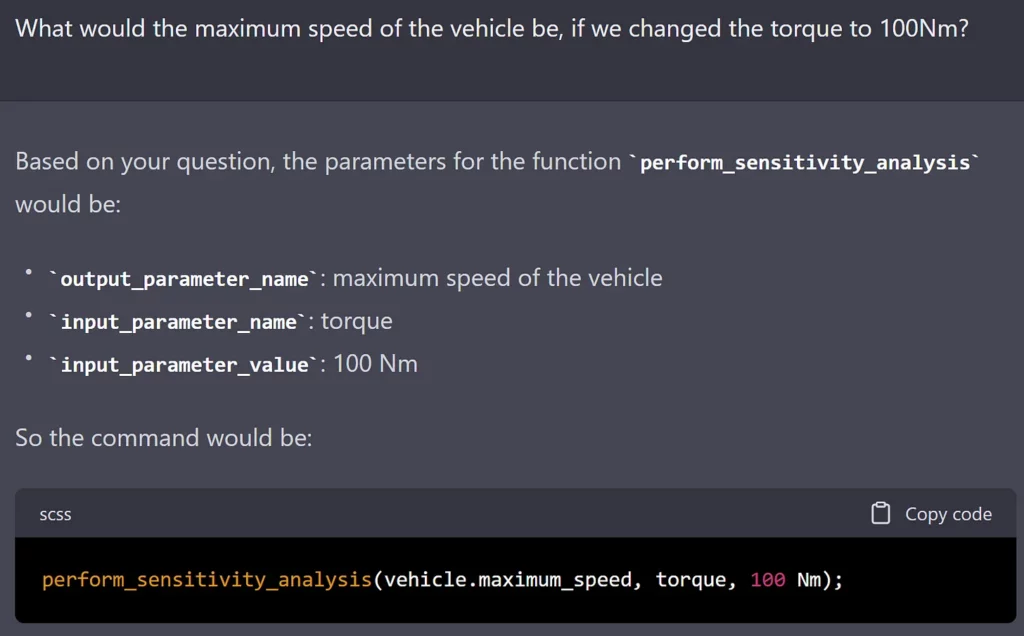

Large language models are (with good prompt engineering) already great today at translating human intent into parameterized functions.

As long as the engineering data is now stored in a collaborative engineering environment with calculation engines, AI Assisted Engineering can provide accurate answers to loosely formulated questions.

AI for an iterative design process

The iterative design process stands as a cornerstone in the quest for design optimization. At its core, this approach involves a cyclical process of prototyping, testing, analyzing, and refining a product or system. With each iteration, the design evolves, growing closer to an optimal solution that balances functionality, aesthetics, usability, and feasibility.

In the realm of hardware, where design decisions have tangible implications for product performance, durability, and cost, the importance of this process cannot be overstated. AI amplifies the power of iterative design by making each cycle more informed and efficient. For instance, after a prototype is tested, AI can rapidly analyze the results, highlighting areas that meet design criteria and those that fall short.

This level of granularity, achieved in mere moments, can guide designers on where to focus their refinements.

Moreover, AI can predict how proposed design changes might impact the next iteration, giving designers foresight that was previously unattainable. Such predictive capabilities expedite the iterative process, ensuring that each loop brings the design closer to optimization without wasting time on less promising avenues.

Furthermore, the iterative design process thrives on feedback. AI, with its data-driven approach, provides consistent, unbiased, and detailed feedback, allowing for micro-adjustments that might be overlooked in a purely human-driven process. Over multiple cycles, these small, AI-informed refinements can culminate in a design that’s holistically optimized, marrying the best of human intuition with machine precision.

In conclusion, the iterative design process, when augmented by AI, becomes a potent tool for design optimization, ensuring that each iteration is a step forward in achieving the pinnacle of design excellence.

Summary

In Assisted Engineering we should treat AI Assistants as our favorite colleagues in the room:

They have a lot of creativity and help us derive design solutions faster.

They do not get tired of performing tedious and repetitive tasks for us.

They have a great memory and their insights bring design tasks forward 10x faster than if they were not in the room.

Since they joined our company we have been able to iterate faster; make less mistakes and come up with better and cheaper designs, leading us to faster time to market.

But just like with any other engineer, we would not trust them and get rid of our quality control or certification process; because they might very well make mistakes as well.

This article was created with the help of Marco Witzmann’s Substack post ‘Today’s AI suck at maths, but developing planes and cars with it is still a good idea‘